Datasheet: Pressure transducer - type S1QP

Technical datasheet

This technical datasheet is valid for pressure transducers S1QP intended for use with S1Q telemetry system. This datasheet details handling and specification of the device and additional basic product information.

Measurement principles

S1QP is designed to measure absolute pressure, underpressure or overpressure in pipes with different types of medium - for example gases and liquids. The processing thread and main measurement body is made from stainless steel of type DIN 1.4301 (AISI 304 / X5CrNi18 10). The analog to digital measurement is done in the body of the transducer and send over a serial line into the S1QX telemetry unit, which, depending on the configuration, sends the compensated data over wireless network to final destination system - such as SCADA / AWS / TTN or other.

The configuration of the measurement place is stored in the memory of the S1QP transducer, not the telemetry unit, therefore the replacement of the telemetry unit does not require new configuration of the measurement place.

Mechanical characteristics

The transducer is enclosed in robust steel cylinder made from stainless steel. The transducer is connected to the telemetry unit using keyed connector and a large plastic screw to secure the two units securely in place. No tools must be used to tighten the plastic screw. Used plastics is made from ASA plastics, which is treated for withstanding suns UV radiation.

Technical parameters

| Type of measurement | absolute pressure, underpressure, overpressure, liquid level (hydrostatic pressure) |

| Type | common or intended for potentially explosive environments (Ex) |

| Max pressure measurement range | 0 - 60MPa |

| Max range of measured medium | -40°C to +125°C |

| Max measurement precision | 0,1% from measurement range for pressures >=25kPa 0,25% from measurement range for all other ranges; precision drift contains non-linearity, hysteresis and reproducibility |

| Additional measurement error due to temperature drift | standard: < 0,03 %/10 °C in range 0°C to + 60°C extended: < 0,03 %/10 °C in range -20 to +60°C |

| Long-term stability | < 0,15 % from range per year |

| Recommended calibration frequency | Once every 1 to 2 years |

| Power supply | from S1QX telemetry module |

| Wireless telemetry options | Bluetooth, LoRaWAN, NB-IoT, Sigfox, WiFi, ZigBee, 802.15.4 |

| Measurement nozzle type | M20x1,5; G½; G¼; other - as required by customer |

| Non-metal parts material | ASA - Acrylonitrile styrene acrylate |

| Metal parts material | DIN 1.4301, resp. AISI 304, rep. X5CrNi18 10 |

| Type of O-ring | O-ring 53(internal diameter)x2mm silicone 70 SHORE |

| Isolation resistance at 500V | RIZ > 2 M Ohm |

| IP rating according to EN 60 529 | IP 65 |

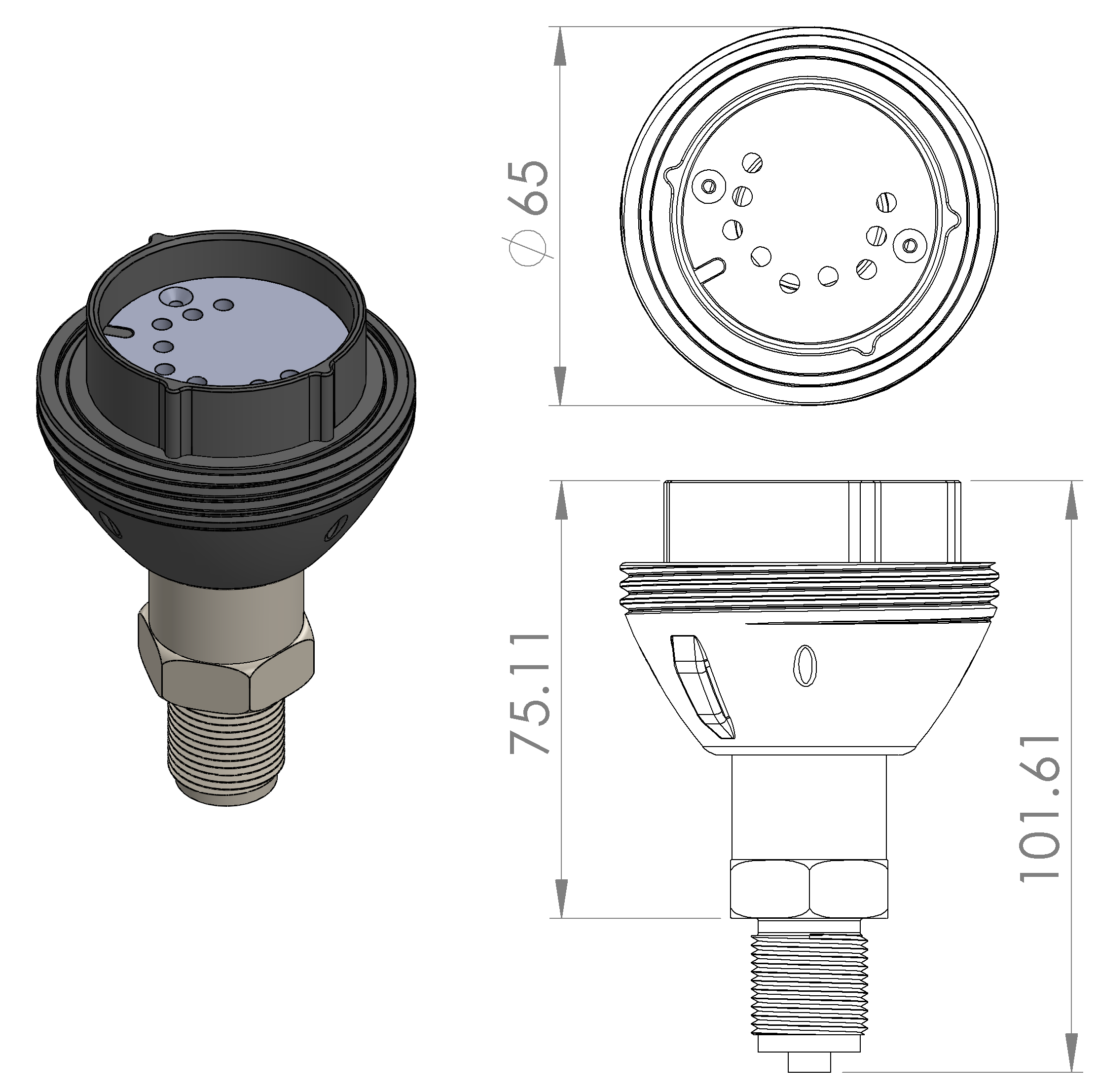

Dimensions

Weight: 185g (+- 30g)

Dimensions in [mm]

Connected to S1QX module

Dimensions in [mm]

Markings and labeling

Information on label:

- Manufacturer and country of manufacture

- Device type

- Full device order specification

- Measurement range

- Measurement precision

- Serial ID

- IP rating

For version intended for use in potentially explosive environments:

- Safety type Ex specification

Ordering

The purchase order shall contain the following information:

- Order reference number and date

- Invoicing and delivery address (including VAT number)

- Parts order numbers from ordering table, number of units requested, requested expedition date

- Type of expedition (for example ex-works, door to door delivery)

- List of additional options

Order codes

| Measurement range (R) | |

| R0 | 0-2.5 kPa |

| R1 | 0-4 kPa |

| R2 | 0-6 kPa |

| R3 | 0-10 kPa |

| R4 | 0-16 kPa |

| R5 | 0-25 kPa |

| R6 | 0-40 kPa |

| R7 | 0-60 kPa |

| R8 | 0-100 kPa |

| R9 | 0-160 kPa |

| R10 | 0-250 kPa |

| R11 | 0-400 kPa |

| R12 | 0-600 kPa |

| R13 | 0-1 MPa |

| R14 | 0-1.6 MPa |

| R15 | 0-2.5 MPa |

| R16 | 0-4 MPa |

| R17 | 0-6 MPa |

| R18 | 0-10 MPa |

| R19 | 0-16 MPa |

| R20 | 0-25 MPa |

| R21 | 0-40 MPa |

| R22 | 0-60 MPa |

| R23 | 80-520 kPa |

| R24 | -100-0 kPa |

| R25 | -100-100 kPa |

| R26 | barometric pressure |

| R27 | 0-2 MPa |

| RX | special - on request |

| Type (V) | |

| V0 | ATEX - zone 2 |

| V1 | standard |

| VX | special - on request |

| Measurement precision in % of measurement range (P) | |

| P0 | - |

| P1 | 0.1% |

| P2 | 0.25% |

| P3 | 0.4% |

| P4 | 0.5% |

| PX | special - on request |

| Type of measurement (M) | |

| M0 | absolute pressure (against vacuum) |

| M1 | underpressure |

| M2 | overpressure |

| M3 | liquid level height |

| MX | special - on request |

| Working temperature (W) | |

| W0 | -20°C to +60°C |

| W1 | 0°C to +60°C |

| WX | special - on request |

| Mounting thread (T) | |

| T0 | M20x1.5 |

| T1 | G1/2 |

| T2 | G1/4 |

| T3 | NPT 1/2 |

| TX | special - on request |

| Type of measurement nozzle (N) | |

| N0 | standard (EN 837) (with raised nozzle) |

| NX | special - on request |

Example: S1QP-R23-V0-P4-M0-W0-T0-NX

NX note by customer: no nozzle, only flat surface with intake

Installation and mounting

Use 27mm spanner to mount the transducer.

Never use tools to tighten the plastic screw of S1QX telemetry unit. Only tighten lightly by hand.

If installing into Ex environment please consult us first for detailed installation instructions.

Consider using surge pressure damper in installations where excess momentary pressure is expected - such as water pipes or other high-density liquids. This can be supplied with the S1QP pressure sensor as an extra option.