Datasheet

P1QP Pressure Sensor Datasheet

Overview

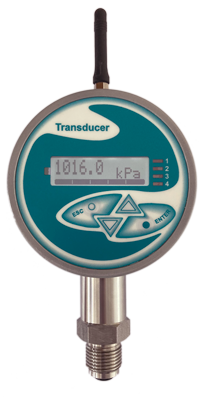

Digital pressure transducer P1QP is a telemetry-enabled, battery powered pressure sensor, which is primarily used to measure pressure in distribution pipes of gases or liquids and sending the measured data over the wireless network into centralized measurement systems such as SCADA.

Wireless communication of the transducer is provided utilizing one of the LoRaWAN, Sigfox, Bluetooth, ZigBee, 805.15.4 or Wi-Fi (2.4GHz, 802.11b/g/n, WPA2) radio technology using various RF frequency spectrums.

Application

Pressure manometer P1QP is designed for precision measurement and wireless transmit of overpressure, under-pressure or absolute pressure of gases or liquids inside distribution piping. The main measurement body is made from stainless steel, so any medium can be measured which does not react with stainless steel type DIN 1.4301, also known as AISI 304 also known as X5CrNi18 10.

In manometer, the pressure the medium creates presses on the mechanical membrane and changes electrical properties of the output signal, which is then electronically amplified and converted to digital numerical form. This measured information is afterwards transmitted over wireless network to the final system for monitoring, metering or controlling purposes.

ATEX information

The device is available in ATEX version as following:

- ATEX zone 2: LoRaWAN and Bluetooth versions available

- ATEX zone 1: Bluetooth version available

- ATEX zone 0: Bluetooth version available

Certification is done according to the European Union legislation.

Mechanical information

The transducer is enclosed in a robust stainless steel enclosure. The back cover is made from UV-stabilized ABS-based plastics.

Technical parameters

| Type of measurement | absolute pressure, overpressure, under-pressure |

| Maximum measurement range | 0 - 60MPa |

| Temperature of measured medium | min. -40°C, max. +125°C |

| Measurement precision | 0,1% of measured range for pressures more or equal to 25kPa 0,25% of measured range for all pressure ranges this combined precision accounts for non-linearity of measurement, hysteresis and repeatability |

| Additional measurement error due to ambient temperature | less than 0,03 %/10°C in the range of 0 to +60°C less than 0,03 %/10°C in the range of -20 to +60°C |

| Long-term precision stability | additional error of less than 0,15% of range per year |

| Recommended calibration frequency | once every two years |

| Power supply | user replaceable battery - order code P1QB |

| Wireless uplink technology | Bluetooth, LoRaWAN, Sigfox, ZigBee, 802.15.4, Bluetooth LE, Wi-Fi (2.4GHz, 802.11b/g/n, WPA2) |

| Antenna connector | SMA external threading |

| Process attachment | M20x1,5; G½; G¼; other - see ordering table below |

| Material of process attachment | DIN 1.4301 (AISI 304 / X5CrNi18 10) stainless steel |

| Material of the dial body | Anodized aluminium or stainless steel |

| Isolation resistance at 500V | RIZ > 2 M Ohm |

| IP protection grade according to (IEC 60 529) EN 60 529 | IP 65 |

| Recommended battery for C0 models: | SAFT LSH 20 or SAFT LS 33600 |

| European HS code: | HS Code 90262020 - Electronic, instruments, apparatus |

Weight and dimensions

Weight ex. battery:

Dimensions in [mm]

LoRaWAN parameters provisioning

LoRaWAN parameters are provisioned via OTAA (Over The Air Activation) and delivered to the customer together with the device on a printed card included in the package.

Measurement packets are sent in regular intervals (configurable via display menu) as unconfirmed uplink messages. Device checks regularly for link connectivity using confirmed uplink messages and re-joins the network automatically if connection is lost.

Power requirements, consumption and battery life

LoRaWAN version

| Parameter | Value |

|---|---|

| Max current during initial power-on: | <230 mA @ 3.6 V |

| Max current consumption during transmission: | <120 mA @ 3.6 V |

Estimated power consumption

The following table summarizes the estimated power consumption of the device in various states of operation with a "good" radio signal strength (most applications will have better signal strength and thus lower power consumption during transmission). Actual power consumption may vary depending on environmental conditions, configuration of the device and quality of the radio signal.

| State | Energy consumption | Note |

|---|---|---|

| Idle (display "off") | <0.64 µWh / min | Sleep mode between measurements, display off |

| LoRaWAN TX cycle | <80uWh / cycle | 1 measurement cycle / period is ~15s |

| Display "on" with permanent measurement | Plus 11.5 µWh / min | Add this to the above values for Idle and / or TX cycle |

Example: Display off, measurement every 5 minutes: * Idle consumption: 0.64 µWh/min * ~5 min = 3.2 µWh * TX cycle consumption: 80 µWh / period = 80 µWh - once every 5 minutes * Total consumption per 5 minutes: 83.2 µWh * Total consumption per day: 83.2 µWh * 288 (5 min periods per day) = 23.9616 mWh * Total capacity of SAFT LS 33600 battery: 19.2 Wh * 0.8 = 15.36 Wh (80% usable capacity) * Estimated battery life: 15.36 Wh / 0.02396 Wh/day = 641 days = 1.75 years at nominal conditions

Example: Display off, measurement every 30 minutes: * Idle consumption: 0.64 µWh/min * ~30 min = 19.2 µWh * TX cycle consumption: 80 µWh / period = 80 µWh - once every 30 minutes * Total consumption per 30 minutes: 99.2 µWh * Total consumption per day: 99.2 µWh * 48 (30 min periods per day) = 4.7616 mWh * Total capacity of SAFT LS 33600 battery: 19.2 Wh * 0.7 = 13.44 Wh (70% usable capacity) * Estimated battery life: 13.44 Wh / 0.00476 Wh/day = 2824 days = 7.74 years at nominal conditions

Software

LoRaWAN packet format - see this link.

LoRaWAN FPort summary (qp-patrol firmware variant p1q-nrf52811-s112-lorawan):

- FPort 1: Measurement uplink (unconfirmed). Payload is the measurement packet (17 or 22 bytes depending on alarm functionality).

- FPort 2: System/control uplink (confirmed). Payload

0x61 ?? ?? ??indicates boot/join; payload0x01is a periodic uplink connectivity check. - FPort 3: Battery uplink (unconfirmed). Payload is 1 byte raw battery indicator (0-255, implementation-defined).

Example parsers are promptly available on request via info@quorumprecision.com

Markings

Information included on the label:

- Manufacturer

- Unit order code

- Measurement range and measurement precision

- Serial number

- IP rating

How to order

Order shall contain the following information:

- Date and internal number of the order

- Name and address (including VAT number where appropriate)

- Order number assembled from order tables including number of units and requested delivery date

- Type of delivery

- Optional extras to include (for example high pressure shock damping filter)

Order codes table

Danger

For all pressures up to 40 MPa: Short-term overload pressure of the sensors is double of its measurement range. Burst pressure is tripple of the measurement range. Pressures above overload pressure may cause sensor damage. Pressures above burst pressure may pose health risk to operators and equipment.

For all pressures above 40 MPa: Short-term overload pressure of the sensors is 1.5-times its measurement range. Burst pressure is double of the measurement range. Pressures above overload pressure may cause sensor damage. Pressures above burst pressure may pose health risk to operators and equipment.

Example: 0-60 MPa sensors max measurement range: 0-60 MPa. Short-term overload pressure: 90 MPa. Burst pressure: 120 MPa.

| Measurement range (M) | |

| M0 | 0 - 2.5 kPa |

| M1 | 0 - 4 kPa |

| M2 | 0 - 6 kPa |

| M3 | 0 - 10 kPa |

| M4 | 0 - 16 kPa |

| M5 | 0 - 25 kPa |

| M6 | 0 - 40 kPa |

| M7 | 0 - 60 kPa |

| M8 | 0 - 100 kPa |

| M9 | 0 - 160 kPa |

| M10 | 0 - 250 kPa |

| M11 | 0 - 400 kPa |

| M12 | 0 - 600 kPa |

| M13 | 0 - 1 MPa |

| M14 | 0 - 1.6 MPa |

| M15 | 0 - 2.5 MPa |

| M16 | 0 - 4 MPa |

| M17 | 0 - 6 MPa |

| M18 | 0 - 10 MPa |

| M19 | 0 - 16 MPa |

| M20 | 0 - 25 MPa |

| M21 | 0 - 40 MPa |

| M22 | 0 - 60 MPa |

| M23 | 80 - 520 kPa |

| M24 | -100 - 0 kPa |

| M25 | -100 - 100 kPa |

| M26 | barometric pressure |

| M27 | 0 - 2 MPa |

| M28 | -1 to 0 kPa |

| M29 | 0 - 2.8 MPa |

| MX | special - on request |

| Uplink radio type (R) | |

| R0 | NB-IoT - band 20 |

| R1 | LoRaWAN - Class A - EU 868 MHz |

| R2 | LoRaWAN - Class A - US 915 MHz |

| R3 | Bluetooth - 2.4GHz |

| R4 | XBee - 2.4GHz |

| R5 | 802.15.4 - 2.4GHz |

| R6 | Sigfox |

| R7 | NONE - no communication, display only |

| R8 | Wi-Fi - 2.4GHz, 802.11b/g/n |

| R9 | USB type B (Modbus) |

| R10 | RS485 (Modbus) |

| RX | special - on request |

| Main display body material (B) | |

| B0 | Stainless steel |

| B1 | Aluminium |

| BX | special - on request |

| Power supply type (C) | |

| C0 | D-size LiSOCl2 3.6V non-rechargeable battery |

| C1 | P1QB-B0-F0 battery module |

| C2 | 26650-size 3.3 - 3.6V rechargeable battery |

| C3 | External rechargeable NiMH battery BP-2 |

| C4 | USB - only for USB uplink type (R9) |

| C5 | 12V DC (1W) |

| CX | special - on request |

| Measurement precision (P) | |

| P0 | 0.1% |

| P1 | 0.25% |

| P2 | 0.4% |

| P3 | 0.5% |

| PX | special - on request |

| Type of measurement (T) | |

| T0 | absolute pressure against vacuum |

| T1 | |

| T2 | underpressure / overpressure against atmospheric pressure |

| TX | special - on request |

| Max ambient temperature range (W) | |

| W0 | -20°C to +60°C |

| W1 | 0°C to +60°C |

| WX | special - on request |

| Mounting thread (H) | |

| H0 | M20x1.5 |

| H1 | G1/2 (BSP-BSPP, ISO 228, DIN 259, BS2776, JIS B0202 (PS)) |

| H2 | G1/4 (BSP-BSPP, ISO 228, DIN 259, BS2776, JIS B0202 (PS)) |

| H3 | NPT 1/2 |

| H4 | clamp type (no threading) |

| H5 | wall installation bracket |

| H6 | NPT 1/4 |

| HX | special - on request |

| Type of measurement nozzle (N) | |

| N0 | standard (with raised nozzle) |

| N1 | clamp (DIN 32676) size 32 (ID of pipe) - material: DIN 1.4301 (US/BS 304) |

| N2 | barometric pressure measurement attachment |

| N3 | ISO KF25 |

| NX | special - on request |

Example order code: P1QP-M0-R1-B0-P3-T2-W1-H0-N0

Interpretation:

Measurement range (M0): 0-2.5 kPa

Uplink radio type (R1): LoRaWAN - Class A - 868MHz

Main body material (B0): Stainless steel

Measurement precision (P3): 0.5%

Type of measurement (T2): underpressure / overpressure

Max ambient temperature (W1): 0C to +60C

Mounting thread (H0): M20x1.5

Type of measurement nozzle (N0): standard (EN 837) (with raised nozzle)

Packaging

Sensors are appropriately packed individually into padded cartons.

The packaging includes all information required for proper use and servicing of the equipment.

Installation

The manometer is screwed on to the measurement place with appropriate spanner (24mm). The inner thread on the measurement place and manometer must match! Tightness of the connection is ensured by appropriate gasket - not part of the delivery. The dial body of the manometer must not be used for tightening of the manometer to the measured place. Always use spanner and dedicated mounting nut.

Support

For support please contact your distributor or manufacturer directly via info@quorumprecision.com